Gas Wizard Heating are your local boiler experts specialising in providing outstanding heating services to Northumberland, Newcastle Upon Tyne, North Tyneside including Bedlington, Blyth and Cramlington.

Get in touch with Gas Wizard Heating for professional boiler care, installation and gas services. Contact us by calling 07890242485 or select the button below for our contact page.

We're on the Gas Safe Register meaning we are fully qualified to take on work on all gas appliances

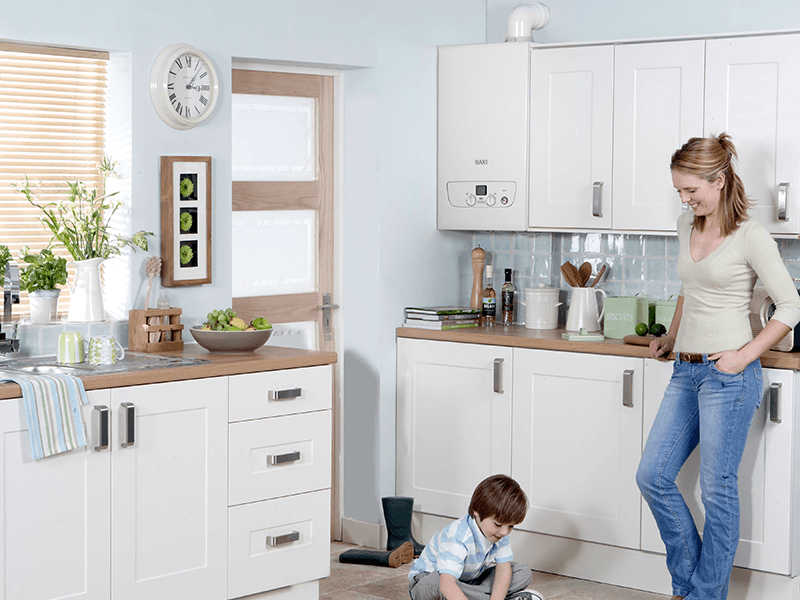

As Baxi Approved Installers, we able to bring extended warranties on selected Baxi Boiler products

We take pride in providing an outstanding service to all of our customers

GET

SOCIAL